Mastering Hose Barb Connections

Midland Industries 3/19/2025

When it comes to fluid and pneumatic systems, securing hose connections is a top priority. Hose barbs are a trusted solution, offering reliability, durability, and ease of use across a range of applications, from automotive cooling systems to industrial fluid transfer. This guide explores the fundamentals of hose barb installation, advanced connection techniques, and best practices to ensure long-lasting, leak-proof performance.

Understanding Hose Barbs and Their Role

Hose barbs are low-pressure hose connectors featuring sharp, ridged barbs designed to grip the inner walls of flexible hoses. This structure helps prevent hose detachment under pressure, making them an ideal choice for:

Air hoses in shop and service environments

Water and fluid transport lines

Automotive cooling and fuel systems

While most hose barbs require a clamp for a secure fit, exceptions exist, such as hose barbs with a yellow ring, which are designed to hold without additional hardware. Additionally, some hose barbs are specifically designed for use with tubing rather than traditional hoses.

Step-by-Step Hose Barb Installation

Proper installation is crucial for preventing leaks and ensuring system efficiency. Follow these steps for a secure connection:

Preparation

Cut the hose squarely using a sharp blade to ensure a flush fit.

Inspect the hose for any cracks or damage that could weaken the connection.

Installation

Apply a light lubricant, such as soapy water or glass cleaner, to reduce friction.

Slide the hose onto the barb until it reaches the base of the fitting.

Position a clamp over the barbed section and tighten securely—without over-tightening—to maintain a proper seal.

Advanced Connections: Hose Ferrules for Maximum Security

For higher-pressure applications or long-term durability, hose ferrules offer enhanced security compared to standard clamps. These cylindrical metal sleeves encase the hose and barb, providing:

Increased durability: Ferrules create a robust and lasting connection.

Leak prevention: Crimping compresses the hose onto the barb, ensuring a tight seal.

Safety: Particularly important for compressed gases and high-pressure fluids, preventing detachment and blowouts.

The Crimping Process:

Slide the ferrule onto the hose before inserting the barb.

Position the assembly within a hose crimper (e.g., Midland 308070), ensuring proper size and pressure settings.

Activate the crimper to compress the ferrule evenly around its circumference.

Inspect the crimped ferrule to confirm uniform attachment and secure sealing.

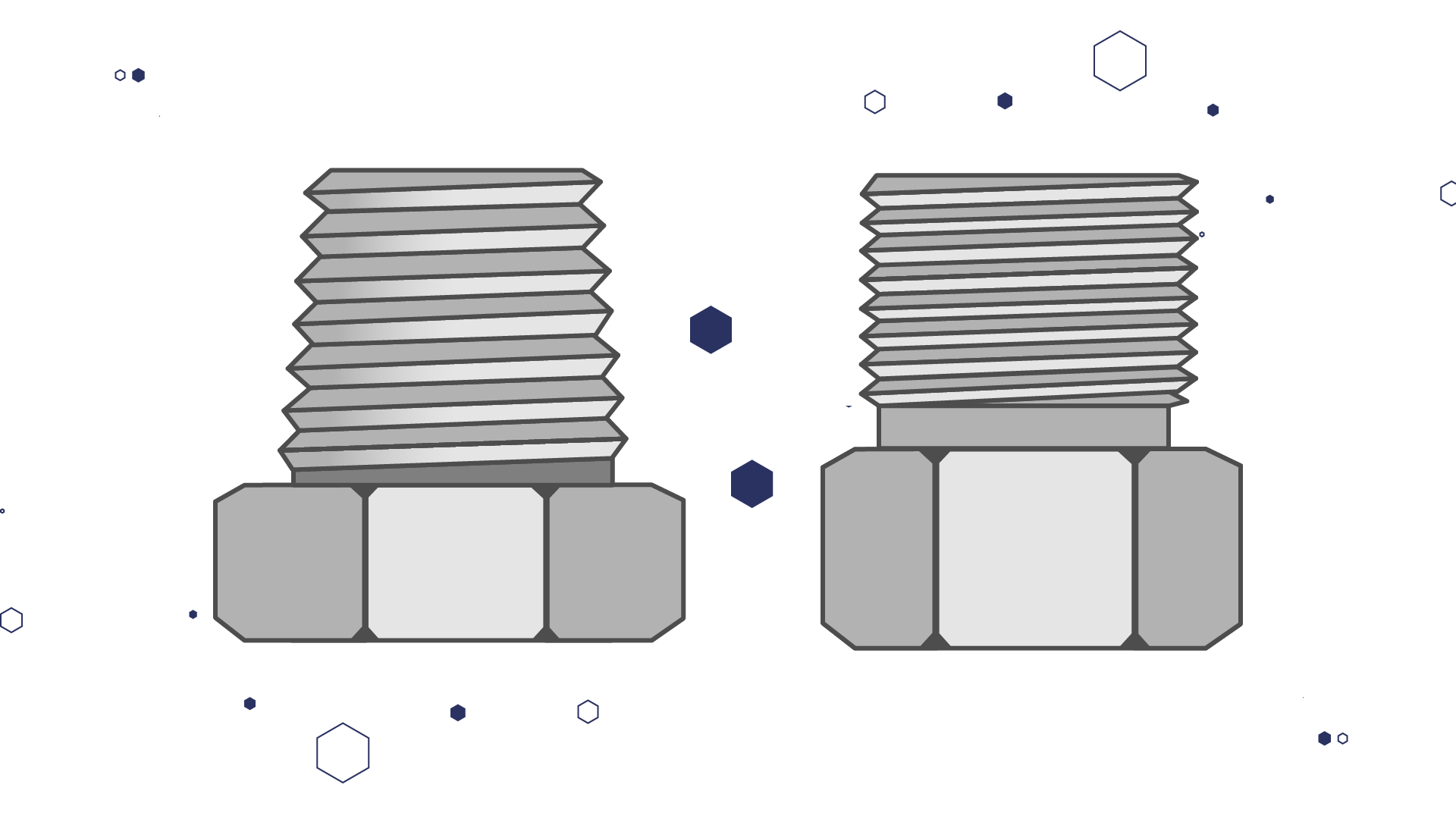

Choosing the Right Hose Barb Connection Style

Different connection styles cater to specific applications. Understanding these options ensures optimal performance:

Pipe Threads: Used in general plumbing and industrial applications for secure, leak-proof connections.

Ball End Swivel & Ballseat: Ideal for applications requiring hose movement, reducing stress and extending hose lifespan.

45° Flare: Provides a metal-to-metal seal for moderate to high-pressure applications like refrigeration.

37° JIC (Joint Industrial Council): Preferred in hydraulic systems due to its resistance to vibration and ability to handle high pressures.

Pipe Threads

Ball End Swivel & Ballseat

45° Flare

37° JIC (Joint Industrial Council)

Key Takeaways for Reliable Hose Barb Installations

By following best practices, you can ensure the longevity and efficiency of your hose connections:

Always cut hoses squarely for a flush, leak-free fit.

Use clamps or ferrules to reinforce connections, ensuring they remain secure under pressure.

Select the correct hose barb and connection style based on system requirements.

Inspect installations regularly to detect wear or potential failures before they escalate.

Elevate Your Expertise with Midland Industries

At Midland Industries, we provide high-quality hose barbs, fittings, and accessories engineered for precision and reliability. Whether you're working in an industrial setting, automotive shop, or home workshop, our products ensure secure, efficient connections every time.

For more insights into best practices for fluid and pneumatic system components, explore our full range of fittings and installation solutions at MidlandIndustries.com.